PRODUCTS

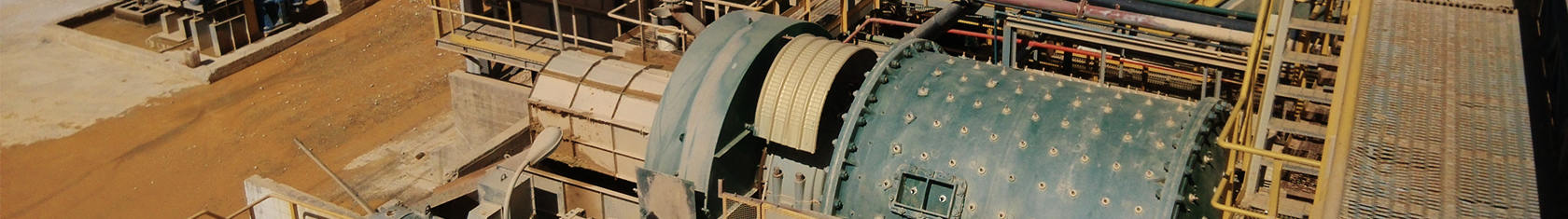

Ball Mill

The ball grinding mill is the key equipment for conducting pulverizing operation after materials are crushed which is widely used in cement, silicate products, new building materials, fireproofing, chemical industry, mineral separation for ferrous metal and non-ferrous metal, glass-ceramic and other industries, is used for crushing and grinding every kind of ore or other grindable materials. In general, it is better to use overflow ball mill when the ore grinding fineness is fine and is better to use grate ball mill when it is coarse. (It is able to prevent adverse effect on sorting from heavily-milled materials)

We're here to help:

0086-21-58386189, 58386176

Easy ways to get the answers you need.

0086-21-58385681

Technical parameter

Related Products

Request for Quotation

You can get the price list and a SBM representative will contact you within one business day.