PRODUCTS

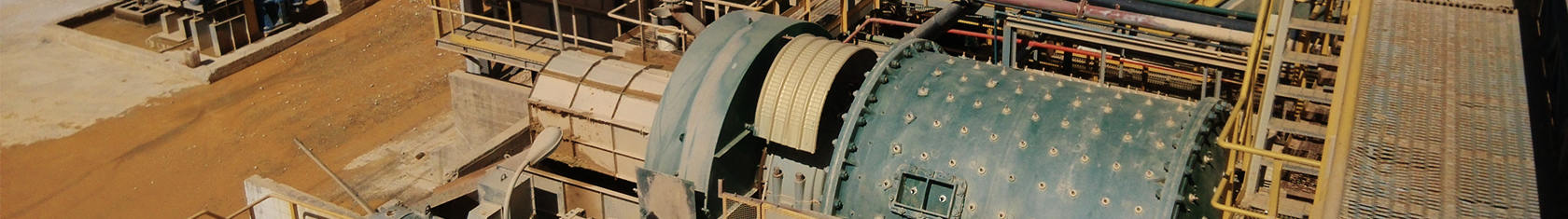

Roller Press

The roller press is composed of two opponent pressing rollers with the synchronous rotation. One is a fixed roller and the other is a movable roller. The materials are fed from the upper side of the two rollers, they are put into the interval of the rollers continually by the pressing rollers, materials change into the contact material cakes after effect of the high pressure and then they are discharged from the machine. With regards to the discharged material cakes, there is not only certain proportion of the fine materials, but also there is a large quantity of cracks in the unfinished granule product. The energy consumption of the powder grinding can be reduced in the process of the further powder grinding.

Features

The machine adopts the welded open-type frame and it is characterized by the excellent stiffness, beautiful appearance and convenient maintenance and inspection.

The structure of four rows of cylindrical roller bearing is adopted, which improves the bearing capability of the equipment greatly, reduces the weight of the equipment and save the installation space.

The hard tooth surface planetary reducer is adopted, the traditional system structure is contact and the operation is stable and reliable.

The special roller surface structure is adopted in the whole-type pressing roller and the service life of the roller surface is increased;

The independent distributed integration oil circuit system owns the stable performance and reliable work capability.

Combined seal roller cover, the sealing effect is better.

PLC procedure controller is adopted, the automatic control is realized in the whole process of the production and the best work situation can be achieved.

Technical parameters

Related Products

Request for Quotation

You can get the price list and a SBM representative will contact you within one business day.